Point

The point of this section is to give data on the various sorts of glass-ionomer concretes accessible and the one of a kind properties of this gathering of materials.

Result

Perusers will better understand how the organization and setting response of glass-ionomer concrete directs its taking care of to streamline clinical execution, including fluoride discharge, bond quality and dimensional security.

Presentation

Glass-ionomer concrete was first made financially accessible in 1976 as a self-glue, tooth-hued filling material called ASPA. It determined its name as an abbreviation of the significant constituents, aluminosilicate glass and polyacrylic corrosive. The early materials were moderate setting and hard to deal with, with generally poor feel. Consequently, there have been significant upgrades in the properties of this significant gathering of materials.

Signs

Current glass-ionomer concrete is an adaptable, “brilliant” dental material, with the accompanying applications:

- conclusive remedial material in low burden bearing regions in grown-ups

- conclusive remedial material for deciduous teeth

- temporary helpful material in grown-ups

- center develop material preceding crown arrangement

- liners and base

- luting concrete for crowns, posts and scaffolds

- crevice sealant

- holding operator for composite tars and dental amalgam.

- Focal points

Glass-ionomer concretes are mainstream materials as they show the accompanying clinical focal points:

- they are tooth-hued

- they bond artificially to tooth substance and non-valuable metals without the requirement for extra cements

- they discharge fluoride

- their coefficient of warm development is proportional to that of tooth structure

- they have great biocompatibility.

- Weaknesses

- The upsides of glass-ionomer concretes are counterbalanced by the accompanying hindrances:

- low break durability, constraining applications in high burden bearing territories

- a few kinds can’t be done and cleaned at a similar visit they are set

- a few sorts are powerless against corrosive disintegration

- a few sorts show low flexural quality and wear opposition.

Sorts of Glass-ionomer Cement

Three primary kinds of glass-ionomer concrete are usually utilized. They have various creations and properties. These sorts are:

- customary glass-ionomer concrete

- customary, high-thickness, strengthened glass-ionomer concretes

- sap altered glass-ionomer concretes

Customary Glass-ionomer Cements

Glass Powders

Customary glass-ionomer concretes comprise of a basic (essential) aluminosilicate glass with fluoride, which responds with an acidic poly(alkenoic) corrosive to make a salt network and water. The glass filler particles are overwhelmingly calcium aluminosilicate glasses, yet certain producers supplant a portion of the calcium with strontium or lanthanum to build concrete radiopacity. An expansion in radiopacity makes it simpler for the clinician to distinguish the nearness of intermittent caries under a reclamation in a radiograph. A wide range of sorts of glasses are utilized, however the basic formulae are:

The glasses get heat treatment during make. This treatment modifies surface reactivity of the powder, as does the molecule size. A decrease in molecule size expands reactivity, giving improved physical properties.

Fluoride is available in the glass powder as calcium and sodium fluoride. At first, it was added as a motion and to improve taking care of properties. The nearness of the fluoride particle adds to the arrangement of complex bodies with the metallic particles, discharged in to the fluid during the setting response. CaF+ and AlF2+ are shaped, which postpone the holding of the metallic cations with either polyacrylic corrosive – to frame calcium and aluminum polyacrylate – or with the COO–bunches in the copolymer chains. This has the impact of easing back introductory setting by gelation and along these lines the working time is extended. Fluoride speaks to around 20% of the last glass powder. At the point when the concrete is blended and set, most of the fluoride is discharged from the recently shaped salt frameworks.

Polyalkenoate Acid

The fluids are high sub-atomic weight electrolytes dependent on homopolymers of acrylic corrosive or copolymers with itaconic or maleic acids. Copolymers were created to improve the time span of usability of the fluid, which tended to turn out to be excessively gooey and unseemly for use after around a half year of stockpiling. The physical properties of a glass-ionomer concrete can be improved by expanding the atomic weight or the convergence of the polyalkenoate corrosive.

Advantages accomplished are, notwithstanding, restricted by the way that the concrete turns out to be too thick to even think about being clinically helpful over specific levels. A few producers have alleviated the impacts of this by freeze-drying the corrosive and including it as a segment in the powder, to be blended in with water alone or a blend of water and tartaric corrosive.

Tartaric Acid

The expansion of 5–10% of optically dynamic L-tartaric corrosive improved the dealing with properties of the concrete by postponing beginning setting, like the activity of fluoride, and afterward giving a fast beginning response. The clinical advantages of this are it gives the clinician longer to control the concrete into the pit and spot a framework whenever required, while shortening the time allotment required for the material to set. What’s more it builds the compressive quality of the concrete.

Water

Water is a fundamental part of glass-ionomer concrete. This recognizes glass-ionomer concrete from most of other tooth-shaded therapeutic materials, which are polymer based and hydrophobic. Somewhere in the range of 11 and 24% of the set glass-ionomer concrete is water, some “approximately” bound, some “firmly” bound. The approximately bound water is handily lost if the relative dampness encompassing a recently positioned rebuilding falls beneath 70%. This is clinically basic, in such a case that the concrete is permitted to dry out, the approximately held water is lost quickly by dissipation, prompting over the top shrinkage. This shrinkage makes the concrete split, trading off style and the physical properties of the concrete. Concrete drying out is well on the way to happen if the concrete is confined under an elastic dam, or is done or cleaned with rotational instruments without the use of water coolant. More slow setting stylish glass-ionomer concretes are helpless against lack of hydration for as long as a half year after position, while the quicker setting materials are less powerless following fourteen days.

Glass-ionomer concrete may likewise be harmed whenever presented to abundance water ahead of schedule in the wake of blending and arrangement. Calcium and aluminum cations required for the setting response (see underneath) can be eluted within the sight of abundance water, which meddles with the setting response, creating frail, unaesthetic concrete with a pasty surface. In this manner, the outside of recently positioned glass-ionomer concrete must be shielded from harm by salivation or untimely mouth washing. Covering the setting concrete with a network and confining the tooth with cotton fleece rolls, along with low-volume pull, most effectively accomplishes this. Promptly the network is expelled, a defensive layer of low-thickness methacrylate-based gum sealant or surface gleam ought to be applied to the outside of the concrete and light-restored. Elective materials for this utilization incorporate oil jam, copal or other exclusive varnishes, however they tend to get permeable and, as a result, moderately inadequate.

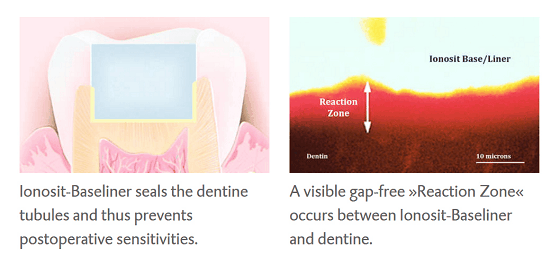

Expert opinion

- Dr. Manan Dhulia Dental Director of Sabka dentist says “The tooth coloured cavity liner serves as a safety barrier for the filling material that is spoiled, broken, or fractured. Ionosit is the perfect call for all the restoration problems.”